3D printing is pretty cool. You can go on various websites and download models of items and your printer will bring them into the real world. When I was getting into the hobby I never found the articles or videos that outlined the reality for a hobbyist. For anyone who is looking to get into 3d printing here is what I would’ve liked to have read back then.

Choose your fighter.

When you are looking to get into this hobby you need a end goal in mind. What is it that you want to print? This will have an impact on the type of printer you will choose. If you are looking to print things like mini figures or similar for table top gaming, resin with its finer detail is the way to go. If you are looking to print large things like for cosplay or more sizable models then you will go down the filament route. Since I wanted to do larger projects (such as the excellent Gridfinity) I chose filament printers.

Assembly may be required.

When I got my printer (an Elegoo Neptune 2S filament printer) I needed to put the printer together. There were comprehensive instructions and some videos online that helped a lot. Once I had finished building the printer I began testing it and dialling it in. Get used to this, especially levelling the print bed. 3D printers are not the normal fairly fool-proof consumer product. They need tweaking and maintenance from time to time. For reference I will re-do my bed levelling one every dozen prints and I clean the print bed every print. As for things like tightening the belts, I would only do that if the printer was showing an issue.

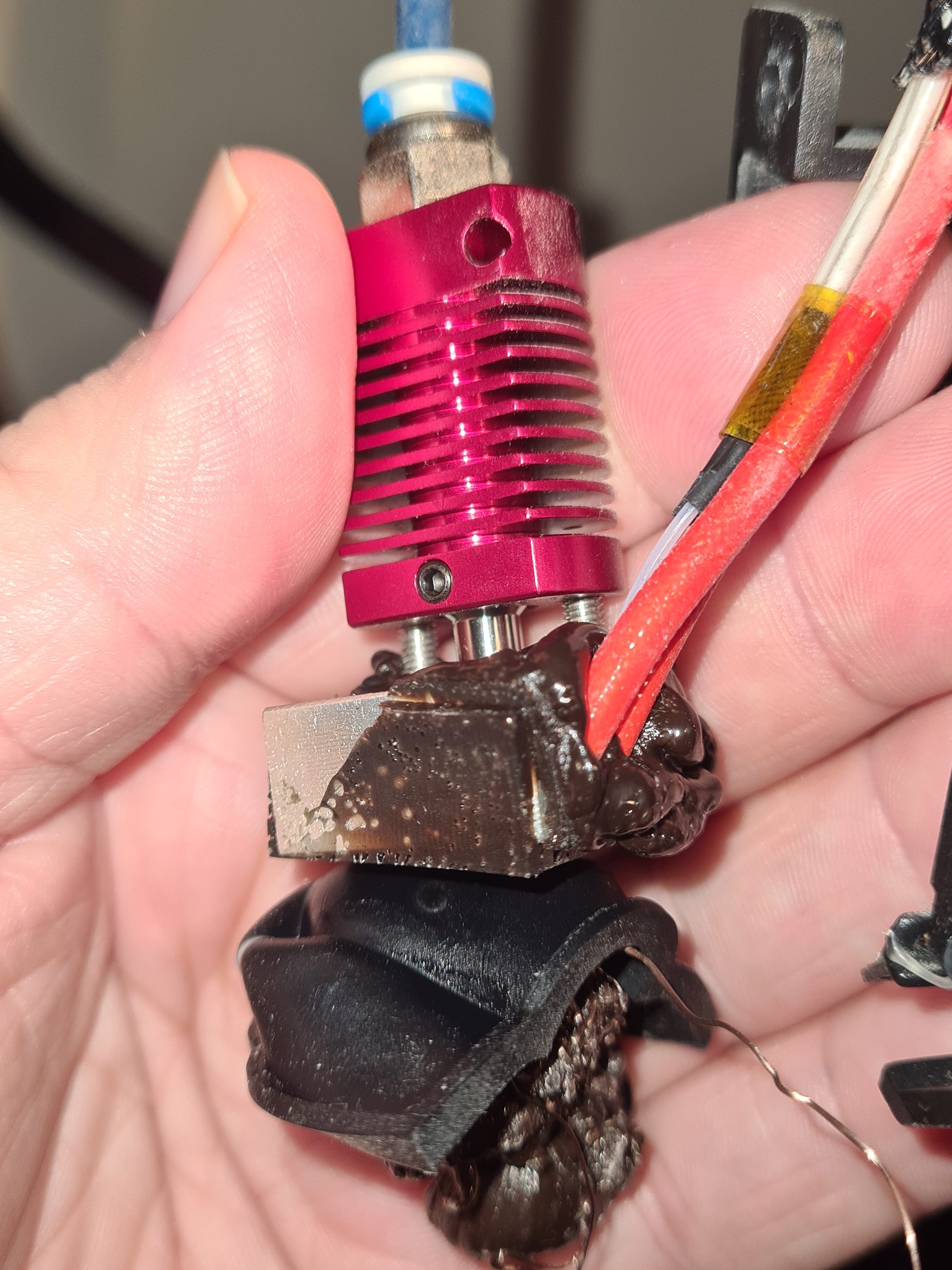

The biggest issue I have had was when something went wrong and a clog in the print nozzle caused plastic to flow backwards and out of the various holes. This is what it looked like;

After trying to remove the plastic and failing I ordered a replacement print head from another company. This required me to do some soldering, rewiring and some creative problem solving. I have since overcome the issue but it was not a drop-in solution by any means. I couldn’t get official parts and had to make adjustments.

Upgrades people, upgrades!

Since purchasing my printer in May of 2022 I have put multiple rolls of filament through it and I have been happy. I have looked at newer printers with jealous eyes with their automatic bed levelling, enclosures, touch screen interfaces and wireless connectivity. However I cannot justify to myself to spend that much money on a new printer when my current one works. That isn’t to say I haven’t upgraded my printer. I’ve replaced the feed spool, adding a cleaning brush for the filament on the way in and getting some dedicated Hex key screw drivers.

I would like to give a mention to the Bamboo X1 Carbon. You have likely seen it in various social media posts where people are just creating cool stuff with minimal effort. Understand this is a different beast altogether. Printers like the Creality Ender 3 (which my printer is based on) are more for the hobbyist whereas Bamboo is offering something that is much closer to the “enterprise” side of things. This printer is much more capable, had a lot more engineering work put into it and has unique features such as their AMS which allows for automatic multi colour printing. But this comes with a serious price tag of nearly £1,500! My printer was less than £300.

A part of the inspiration for this entry was from a recent YouTube video by Makers Muse where he discusses the Ender 3 and why so many 3d printers look the same.

Overall I would recommend the hobby to those people who are technically minded and are happy to tinker and fettle. If this puts you off but still want to build things, I would recommend you look into model kits.

Leave a comment